Best Rotary Cutters for Quilting Your Essential Guide

Best Rotary Cutters for Quilting Your Essential Guide: Tired of wonky, imprecise cuts slowing you down? The truth is, the best rotary cutter is the one that fits your hands and your projects. For most quilters, that means starting with a versatile 45mm blade, a comfortable ergonomic handle to keep wrist fatigue at bay, and safety features you can count on.

A quality cutter is the answer to those frustrating fabric struggles—it’s an absolute must-have for anyone serious about their craft. At Linda's, we have all the amazing products you need to finish your next quilting project with precision and ease.

Why the Right Rotary Cutter Is a Game Changer

Moving from scissors to a rotary cutter is a huge leap forward for any quilter. This simple tool, which looks a bit like a pizza cutter, was built for one thing: delivering perfectly straight, clean cuts through multiple layers of fabric with incredible speed and accuracy.

This educational guide will walk you through what really matters when picking your cutter. We’ll look at how blade size affects everything from tiny, intricate curves to long, straight borders. You’ll also see why a comfortable handle isn't just a nice-to-have—it’s essential for those marathon quilting sessions.

Think of this as your personal consultation for finding a tool that feels like a natural extension of your own hand, setting you up for project success.

You're Part of a Huge Quilting Community

The rotary cutter is an essential tool for a massive and passionate community. In fact, the quilting market in the United States and Canada is projected to hit around $5 billion in sales by 2027, driven by 9 to 11 million active quilters just like you. The tool's ability to slice through several fabric layers at once is a huge reason why it’s a cornerstone of the modern quilting studio.

Of course, a great cutter is just the start of a rewarding journey. As you build out your toolkit for your next project, explore our comprehensive list of quilting supplies for beginners to make sure you have everything you need.

With the right tools from Linda's, you can bring any vision to life with precision and ease.

How to Choose the Right Blade Size and Type

The blade is the real heart of your rotary cutter. Getting the right one isn't just about grabbing the most common size off the rack; it's about matching your tool to the task for those perfectly clean cuts every quilter dreams of. This educational step is crucial for the success of your project.

For most of your day-to-day quilting, the 45mm blade is the undisputed champion. It hits that sweet spot between power and control, making it perfect for zipping through fabric strips, squaring up blocks, and tackling the majority of quilt patterns. It’ll slice through 4 to 6 layers of cotton without a problem, which is exactly why you'll find one in nearly every quilter's sewing room.

But sometimes, a project calls for a little more finesse, and that's when a smaller blade really gets to shine.

Matching Blade Size to Your Project

Your trusty 45mm blade can't do it all. When you're working on something intricate, like appliqué pieces or tight curves, the 28mm blade gives you far better maneuverability. That smaller size means more control, so you're less likely to accidentally slice into a neighboring piece. Think of it as the artist's choice for detailed work.

On the other end of the spectrum, you've got the 60mm blade. This is the powerhouse you pull out for the big jobs. Need to cut through multiple layers of fabric and batting all at once? This is your tool. If you’re prepping a large quilt and have long, straight strip sets to cut, this bigger blade will save you a ton of time and keep every layer perfectly aligned.

The key takeaway here is that blade size is never a one-size-fits-all deal. The best rotary cutters let you swap blades easily, so you can go from a big 60mm for batch cutting to a tiny 28mm for delicate appliqué work in the same afternoon.

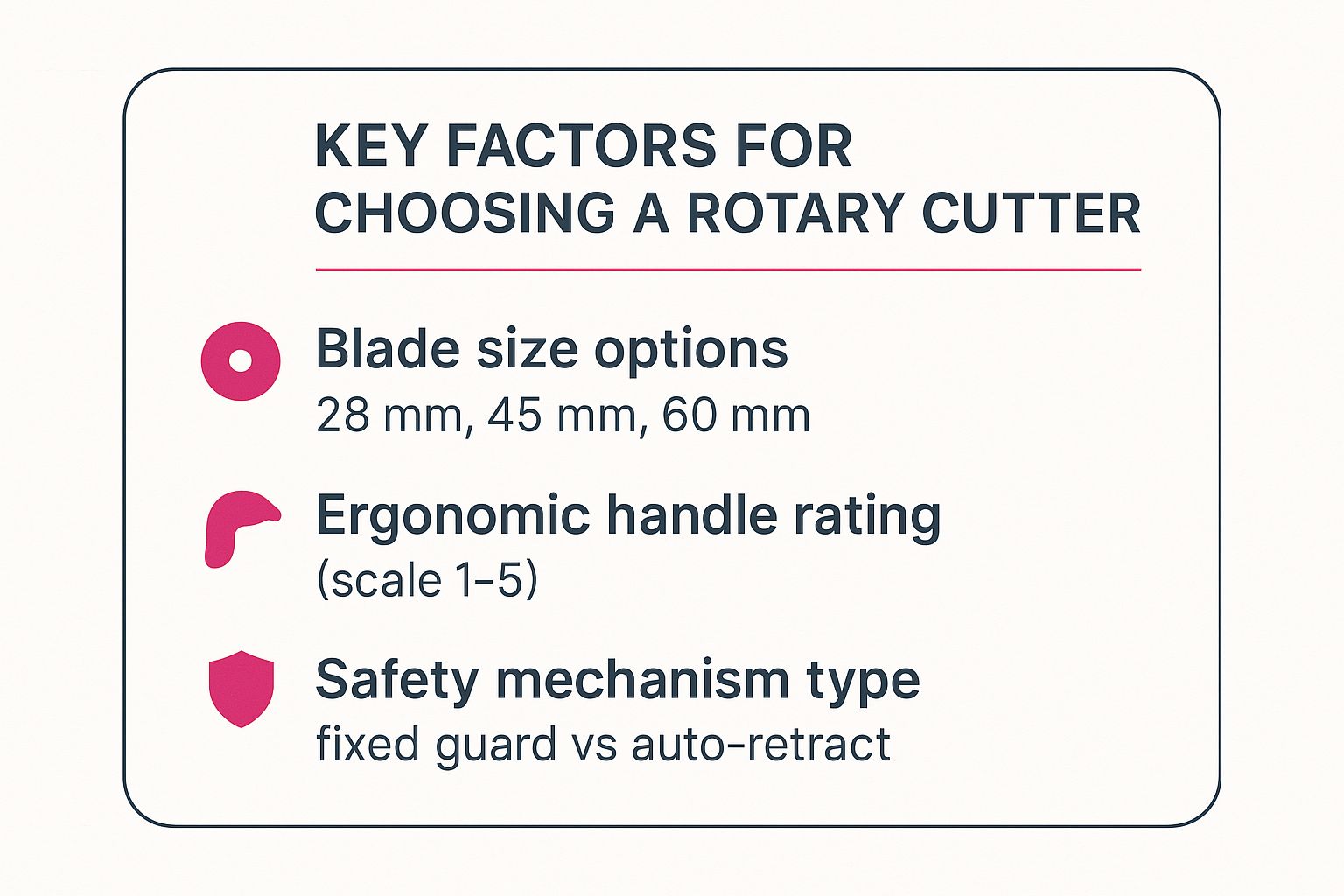

This infographic breaks down the key things to look for, from blade sizes to handle styles and safety features.

As you can see, picking the right blade for your task is just as important as how the cutter feels in your hand.

Beyond Size: Blade Material and Specialty Types

The material of the blade itself also makes a huge difference in how it performs and how long it lasts. Most standard blades are made from a pretty durable tungsten steel. But for those of us who are cutting fabric all the time, upgrading to titanium-coated blades is a smart move. They simply stay sharper for much, much longer.

In fact, big improvements in blade materials and safety locks are a major reason rotary cutters have become so popular. These advancements help solve common frustrations like blades dulling too quickly or the risk of accidents from improper handling. You can actually explore more insights on rotary cutter market trends at Allied Market Research.

And don't forget about the fun stuff! Specialty blades, like wave or pinking styles, are fantastic for adding a decorative, no-fray edge to your fabric projects.

Ready to find the perfect blade for your next creation? Stop by Linda's to explore our amazing selection of rotary cutters and blades to finish your project with precision.

Matching Handle Design to Your Cutting Style

Ever get that nagging ache in your wrist after a long cutting session? The culprit is almost always the handle design of your rotary cutter. The best tool should feel like an extension of your hand—secure and comfortable, never awkward or clumsy.

The right handle for you really depends on your cutting style and the kinds of projects you tackle most often. Let's break down the two main options you'll find out there.

The Classic Straight Handle

The traditional straight handle, sometimes called a "stick" cutter, is a classic for a reason. Its straightforward design is all about simplicity and control.

This style encourages direct downward pressure, which a lot of quilters find perfect for slicing through long, straight strips of fabric. Because your hand sits a bit higher, it gives you a fantastic, clear line of sight over your ruler.

If you spend hours batch-cutting sashing and border strips for your next project, this ambidextrous workhorse is probably your best friend. Just flip it over in your hand, and it works for lefties and righties alike without any blade adjustments.

The Modern Ergonomic Handle

On the other hand, ergonomic handles are contoured to fit the natural curve of your palm. This shape can make a massive difference in reducing hand and wrist strain, especially during those marathon quilting sessions.

These handles are a lifesaver for anyone dealing with arthritis or carpal tunnel. They require less gripping force to maintain control, which helps you keep a more neutral, comfortable wrist position.

If you find yourself cutting a lot of complex shapes, curves, or tiny pattern pieces, the enhanced control of an ergonomic grip can be a total game-changer. Just imagine trimming dozens of small flying geese units—the comfort and maneuverability of a contoured handle make the job feel so much less tedious.

Many of these models even have soft, cushioned grips that absorb even more pressure. When you’re ready to upgrade your comfort and precision, come see the amazing selection of cutters at Linda's. Our team can help you find the perfect tool to finish your project with ease.

Safety Features That Keep You Cutting Confidently

Let's be honest: a rotary blade is incredibly sharp. Choosing a cutter with solid safety features means you can focus on your creative flow instead of worrying about a trip to the emergency room. The best designs integrate safety so seamlessly that it becomes second nature, never getting in the way of your work.

The Two Main Types of Blade Guards

Most cutters you'll encounter use one of two systems:

-

Manual Sliding Guard: This is the classic design. You use your thumb to slide a plastic cover back and forth, exposing or hiding the blade. It's simple, totally reliable, and gives you complete control. The blade is either out or it's in—no surprises.

-

Pressure-Sensitive System: This is a fantastic innovation, especially for quilters who do a lot of stop-and-start cutting. The blade automatically retracts the moment you lift the cutter off your mat. A quick squeeze of the handle exposes the blade, and as soon as you let go, it snaps back to safety. It’s an amazing safeguard against accidental slips or those moments you get distracted.

Many of the most popular cutters today actually combine these two ideas. You might get a comfortable, ergonomic handle with a pressure-activated blade, but it will also have a separate lock to secure the blade in the closed position for storage or travel.

This dual-system approach is a non-negotiable feature if you have curious kids, grandkids, or pets who might wander into your sewing space. Being able to physically lock that blade down adds a critical layer of security, ensuring it can’t be exposed by an accidental squeeze of the handle.

When you're picking out your next cutter, think about how you work. Do you prefer the deliberate control of a manual slide? Or would an automatic guard better suit your fast-paced, piecing-heavy style? Finding the right fit will give you the peace of mind to tackle any project with confidence.

Ready to find a cutter that keeps you safe and your cuts precise? Explore the amazing selection at Linda's, where you'll find all the supplies you need to finish your next masterpiece.

Maintaining Your Cutter for Lasting Precision

A well-maintained rotary cutter isn't just a tool; it's your most reliable partner in the sewing room. There’s nothing more frustrating than a dull blade or a sticky mechanism snagging your beautiful fabric and ruining what should have been a perfect cut. A little bit of simple maintenance goes a long way, ensuring your cutter stays in top shape and delivers the precision your projects deserve.

Keeping your cutter clean is the easiest first step. After a big project, you’ll be surprised how much lint and tiny fibers can build up inside the blade housing. This gunk can cause the blade to drag or rotate unevenly, so a quick wipe-down keeps it gliding smoothly.

Blade Care and Replacement

Knowing when and how to change your blade is absolutely critical for both safety and accuracy. A dull blade forces you to press down harder, which is a recipe for slips and crooked cuts. There’s no magic number for blade life, but a good rule of thumb is to pop in a new one after every two or three large quilts. Or, more simply, the moment you notice it skipping threads.

When you do swap out the blade, pay close attention to the screw tension. It's a delicate balance.

- Too Tight: The blade won't spin freely, and you'll feel it dragging across the fabric instead of rolling.

- Too Loose: The blade will wobble, creating wavy, imprecise cuts that are impossible to fix.

You're aiming for a setting that’s just snug enough to hold the blade securely while still letting it spin without any effort. Getting this right is key for those satisfyingly smooth cuts, especially when you’re slicing through multiple layers of fabric and batting. Speaking of which, our guide on creating stunning quilts with the right batting can help you pair those materials perfectly for your project.

A self-healing mat is non-negotiable. Seriously. Cutting on any other surface will dull a new blade almost instantly, wasting your time and money.

These amazing tools have truly changed the game for quilters and crafters. In fact, in 2024, the rotary cutters market was valued at approximately USD 261.86 million and is only expected to grow. You can read the full research on the rotary cutters market if you want to dive into the trends.

By taking a few minutes for proper care, you ensure your cutter performs beautifully for years. Stop by Linda’s to get all the amazing products you need to finish your next quilting project.

Common Questions About Rotary Cutters

Even after years of quilting, a few tricky rotary cutter questions always seem to surface. We've all been there! Getting straight answers can be the difference between a joyful, precise cutting session and a frustrating one. Let's tackle some of the most common issues we hear about in the shop to help you with your projects.

Why Is My Cutter Skipping Threads?

This is easily the most common headache quilters face—you’re gliding along, and suddenly the blade jumps, leaving tiny uncut threads behind. It’s maddening.

Nine times out of ten, this means your blade is either dull or has a microscopic nick you can't even see. Any tiny imperfection is enough to snag and skip over fabric fibers instead of slicing cleanly through them. The very first thing to do is pop in a fresh blade.

If a new blade doesn't fix it, there are two other culprits to check. Make sure you’re applying firm, consistent pressure straight down along your ruler. And take a look at your self-healing mat—if it has deep grooves from repeated cuts in the same spot, the blade can get trapped and skip.

The fastest and most reliable fix for skipped threads is always a new blade. While blade sharpeners are out there, they rarely bring a blade back to its factory-sharp perfection. It's just not worth the frustration when starting a new project.

How Many Layers Can I Safely Cut at Once?

Ah, the age-old question of efficiency! How many layers can we really get away with? This depends almost entirely on your blade size.

Your standard 45mm blade, which is what most of us use for general quilting, can comfortably cut through four to six layers of quilting cotton. If you step up to a bigger 60mm blade, you can often slice through six to eight layers without a problem.

My best advice? Always do a quick test on a scrap piece of your fabric stack first. This little check ensures your blade is sharp enough to cut through every single layer cleanly without causing the bottom pieces to shift or stretch. Cutting fabric correctly sets the stage for accurate piecing. Speaking of which, choosing the right components is key, which is why we have a whole guide on choosing the best batting for quilts that complements this advice perfectly.

Ready to tackle your next masterpiece? Swing by Linda's Electric Quilters to explore all the amazing tools and get the expert advice you need to make it happen. Shop our full collection of rotary cutters and quilting supplies today!