Welcome to the exciting world of machine embroidery, where every single stitch helps tell a story. When you get right down to it, the most important choice you'll make for any project isn't the design file—it's the thread. This one element is what truly dictates the final texture, the sheen, and even the durability of your creation, turning a good design into something absolutely spectacular.

Why Your Thread Choice Is the Secret to Stunning Embroidery

Think of your embroidery thread as the lifeblood of your project. Choosing the right thread for embroidery machines is a lot like an artist picking out the perfect paint; the material and color are what define the mood and quality of the final piece. A poor choice can lead to frustrating thread breaks and a dull, lackluster result. But the perfect thread? That’s what glides through your machine to produce flawless, professional-looking embroidery every time.

This guide is your complete roadmap to navigating what can feel like an endless aisle of options. Our goal is to transform any confusion you might have into pure creative confidence, breaking down everything you need to know to make the right call for every project that comes off your machine.

Building Your Foundation of Knowledge

Once you master thread selection, you’re empowered to stitch out any design with real precision. You'll quickly move beyond just picking pretty colors and start thinking like a seasoned pro, considering how each thread type will interact with your fabric, your needle, and the density of the design itself. This foundational knowledge is what really separates hobbyists from true artists.

In this guide, you will learn to:

- Tell the difference between workhorse fibers like tough polyester and silky rayon.

- Understand the subtle but critical details of thread weight and how it impacts your design.

- Pair the right needle with your chosen thread to stop common issues before they start.

- Select the ideal thread for specific jobs, from tiny, delicate lettering to dense, full-coverage fills.

When you understand the properties of different threads, you can actually predict how a design will look and feel before you even stitch the first color. This kind of foresight saves time, cuts down on wasted materials, and ultimately leads to more beautiful and durable embroidery.

From Quilting to Embroidery

Many of us, especially quilters, find that machine embroidery opens up a whole new world of personalization. The good news is that the principles of fiber quality and durability are universal. Just like you carefully select specific threads for piecing and quilting, choosing the right embroidery thread is the key to beautifully embellishing your projects.

To learn more about this, check out our guide on the best thread for quilting, as many of those core concepts apply here, too.

By the end of this guide, you'll have the confidence to select the perfect thread to bring your creative vision to life, ensuring every stitch is a success. Ready to elevate your craft? Explore Linda's premium collection of embroidery threads and get started on your next masterpiece today.

Decoding the Language of Embroidery Thread

Picking the right thread for your project is a lot like an artist choosing their paint. Every type offers a totally different finish and feel, and the thread for embroidery machines you land on will make or break your final piece. It affects everything from the design’s look to how smoothly your machine even runs. Let’s dive in and demystify the threads you’ll run into, so you can pick the perfect one every time.

While embroidery is an age-old craft, the threads we use today are wonders of modern engineering, designed for incredible strength and color that just won't quit. Polyester has become a huge player, making up 60-70% of the entire embroidery thread market—a market worth hundreds of millions of dollars. It's safe to say we've come a long way from simple natural fibers!

Polyester: The Durable Workhorse

Think of polyester as the all-terrain vehicle of the embroidery world. It’s tough, it’s resilient, and it is built to last. This makes it the undisputed champion for anything that’s going to see a lot of wear and tear or frequent trips through the washing machine. I’m talking about kids' clothes, towels, and work uniforms.

Polyester thread holds its own against bleach and harsh detergents, which means your beautiful, vibrant designs stay bright and true, wash after wash. No fading, no bleeding. It also has a really attractive, subtle sheen that looks fantastic on a huge range of designs.

Rayon: The Silky Artist

If polyester is the sturdy workhorse, then rayon is the elegant show horse. Rayon is famous for its brilliant, high-sheen finish and a silky texture that drapes gorgeously with fabric. When you want a luxurious, high-end look, rayon is your go-to.

But that beauty comes with a trade-off. Rayon isn't quite as durable or colorfast as its polyester cousin. It’s a bit more delicate and can be damaged by bleach, so it’s best reserved for projects that won’t be laundered aggressively. Think wall art, decorative pillows, and special-occasion garments where you want that stunning, lustrous effect to shine.

Cotton: The Timeless Classic

For a soft, matte finish that synthetic fibers just can't duplicate, you turn to cotton. Its gentle, low-sheen appearance is absolutely perfect for quilting, redwork, and creating vintage-inspired pieces where you want the embroidery to have that classic, handcrafted feel.

Because cotton has very little stretch, it's a fantastic choice for creating crisp, well-defined stitches on stable woven fabrics. It blends seamlessly into natural-fiber projects, giving them an authentic, heirloom quality.

As you start building your collection of threads and other key tools, you might find our guide on sewing supplies for beginners to be a great starting point.

Specialty Threads: The Wow Factor

Sometimes, a project just needs that little extra something to make it pop. That's where specialty threads come into play, letting you add unique and dazzling effects that standard threads simply can't deliver.

- Metallic Threads: These threads have a fine metal foil woven in, creating a brilliant, eye-catching sparkle. They're perfect for adding festive flair to holiday projects or a touch of glam to evening wear. Just be aware they often need a special needle and a slower machine speed to prevent shredding.

- Variegated Threads: With variegated thread, a single strand holds multiple colors that change as you stitch. This creates beautiful, organic color shifts in your design, which is amazing for adding depth and dimension to things like leaves, water, or sunsets.

- Glow-in-the-Dark Threads: Yep, it's exactly what it sounds like! This thread soaks up light and then glows when the lights go out. It’s a super fun choice for kids' pajamas, Halloween costumes, or any project where you want a playful, surprising twist.

Embroidery Thread Type Comparison

To help you decide at a glance, here’s a quick-reference table breaking down the most common thread types you’ll find on our shelves.

| Thread Type | Primary Use | Sheen Level | Durability | Pro Tip |

|---|---|---|---|---|

| Polyester | Everyday items, apparel, uniforms | Medium-High | Excellent | The go-to choice for items needing frequent laundering. |

| Rayon | Decorative items, high fashion | High | Good | Offers the best sheen but avoid using bleach on it. |

| Cotton | Quilting, vintage designs, redwork | Low (Matte) | Very Good | Ideal for a natural, hand-stitched appearance. |

| Metallic | Accents, holiday, formal wear | High Sparkle | Fair | Use a Metallica needle and slow your machine speed. |

Once you get a feel for the unique personality of each thread type, you can choose your materials with confidence and bring your creative vision to life. Ready to get started? Stop by Linda's to find the perfect thread for your next project.

Matching Thread Weight and Needles for Flawless Stitches

Getting a handle on thread weight is what separates good embroidery from great embroidery. Think of it like an artist choosing between a fine-point pen and a thick marker—the thickness of the line completely changes the final piece. This simple idea is your secret weapon for creating designs that look truly polished and professional.

When you see a number like 40 wt on a spool of thread, it’s a direct measure of its thickness. It can feel a little backward at first, but with thread weight, a higher number actually means a thinner thread.

Once you get the hang of it, this knowledge becomes your creative superpower. It lets you pick the perfect thread for whatever your design demands, from bold, solid fills to the most delicate, tiny details.

Understanding the Thread Weight System

Let's break down the common weights you’ll see on the shelves here at Linda's Electric Quilters. Each one has a job it's perfectly suited for, helping you get the exact texture and definition you're picturing in your head.

- 40 wt Thread: This is your go-to, the workhorse of the embroidery world. It’s versatile, strong, and the perfect choice for the vast majority of designs, from appliqué to everyday decorative stitching.

- 60 wt Thread: Think of this as your ultra-fine pen for detailed work. It’s the thread you grab for tiny, crisp lettering or intricate lacework where every single stitch needs to be sharp and clear.

- 30 wt Thread: This is your bold marker. Its thickness gives you fantastic coverage, making it ideal for dramatic, dense fills or for topstitching that you really want to pop.

The real magic happens when your machine, needle, and thread are all working together in perfect harmony. If any one of those is out of sync, you’re setting yourself up for headaches like shredded thread, skipped stitches, and puckered fabric.

This passion for home embroidery is growing fast. The global embroidery machine market was valued at around USD 2.2 billion in 2025 and is expected to hit USD 2.98 billion by 2032. This isn't just a niche hobby; it's a worldwide movement of creators and small businesses embracing automated embroidery.

The Critical Partnership of Thread and Needle

The needle you choose is every bit as important as the thread itself. The eye of the needle has to be the right size for the thread to glide through effortlessly. Jamming a thick thread through a tiny needle eye is a recipe for constant breaks and frustration.

For anyone just starting out on this amazing journey, our guide on deciding on a sewing machine has some great recommendations to help you find the right machine for your embroidery dreams.

A correctly sized needle protects both your thread and your fabric, giving you that smooth, beautiful stitch-out we’re all chasing. Needle sizes are usually shown with two numbers, like 75/11. The first is the European size and the second is American—in both systems, a bigger number means a bigger, stronger needle.

Needle and Thread Pairing Guide

Here’s a quick-reference chart to get you started. Matching the right needle to your thread and fabric is the best way to guarantee a beautiful result every single time.

| Thread Weight | Recommended Needle Size | Best For |

|---|---|---|

| 60 wt (Thin) | 65/9 or 70/10 | Small lettering, delicate fabrics, and fine details. |

| 40 wt (Standard) | 75/11 or 80/12 | General embroidery on medium-weight fabrics like cotton or denim. |

| 30 wt (Thick) | 90/14 | Dense fills, topstitching, and heavy fabrics like canvas. |

By taking a moment to match your thread weight to the right needle, you're setting your project up for success from the very first stitch. It’s a small step that makes a world of difference in the quality of your finished embroidery.

Building Your Embroidery Support System

Even the most beautiful, vibrant thread for embroidery machines is only half the story. To get those crisp, professional-looking designs you’re dreaming of, your thread needs a solid support system. This is where stabilizers and bobbin thread come into play—they are the unsung heroes working behind the scenes to make sure every stitch is perfect.

Think of stabilizer as the foundation for a house. Without a sturdy base, the whole structure can get wobbly and weak. It’s the same with embroidery. Stabilizer gives your fabric the support it needs, preventing it from stretching, puckering, or shifting around while the machine lays down dense patterns of stitches.

Choosing Your Foundation: Stabilizer Types

The type of fabric you're stitching on is the single biggest factor in choosing the right stabilizer. Each one has a very specific job, and matching them up correctly is the first step to a flawless stitch-out. Getting this pairing right isn't just a suggestion; it's a must for quality embroidery.

- Cut-Away Stabilizer: This is your best friend for anything with stretch, like t-shirts, sweatshirts, and cozy fleece. It provides a permanent, super-stable foundation that stays with the garment even after washing, preventing the design from warping or losing its shape over time.

- Tear-Away Stabilizer: Got a stable, woven fabric? Reach for tear-away. It’s perfect for sturdy materials like denim, canvas, or quilting cotton. Just as the name implies, you can simply tear away the excess stabilizer when you're done stitching for a clean finish.

- Wash-Away Stabilizer: This stuff is pure magic—it dissolves completely in water. It’s the go-to for delicate fabrics like organza or when you're making freestanding lace, where you absolutely don't want any backing to show.

Of course, beyond the specialized gear, having good general crafting tools is key. For example, A reliable measuring tape is invaluable for getting your design placement just right, which is a huge part of your project's support system.

The Crucial Role of Bobbin Thread

Now let’s talk about the other key player on your support team: the bobbin thread. This is not the place to use your regular top thread! Specialized bobbin thread is designed to be a crucial counterpart—it's much finer and lighter, usually a 60 wt or even a feather-light 90 wt.

Why does this matter so much? A lightweight bobbin thread reduces bulk on the back of your embroidery, keeping the finished project soft and flexible instead of stiff as a board. More importantly, it helps you achieve balanced tension, which lets that beautiful top thread be the star of the show.

Using the correct lightweight bobbin thread is one of the easiest ways to immediately improve your embroidery quality. It ensures the top and bottom threads form a perfect lock stitch, preventing that pesky white bobbin thread from peeking through on the front of your design.

For quilters just dipping their toes into embroidery, this idea of a support material should feel familiar. Just as you carefully select the right batting to get the warmth and loft you want, choosing the right stabilizer and bobbin thread provides the essential structure for your stitches. If you want to dive deeper into that comparison, check out our in-depth article, Quilting A Guide to Batting Choices for the Passionate Quilter.

Pre-Wound Bobbins Versus Winding Your Own

When it comes to bobbins, you’ve got two paths, and the right one for you often comes down to convenience versus control.

Pros of Pre-Wound Bobbins:

- Convenience: They're ready to pop right into your machine, which is a fantastic time-saver.

- Consistency: These bobbins are wound by machines to have incredibly even tension, which can lead to smoother stitching.

- More Thread: They often hold way more thread than a bobbin you wind yourself, meaning fewer interruptions to change it out.

Pros of Winding Your Own:

- Cost-Effective: In the long run, buying a large spool of bobbin fill and winding your own is usually easier on the wallet.

- Customization: It gives you the freedom to use any color or type of bobbin thread you want for specific projects.

By getting comfortable with these essential components—stabilizer and bobbin thread—you’re creating a complete system for success. Stop by Linda's to stock up on all the essential stabilizers and bobbin threads you need to support your creative vision and truly perfect your projects.

Solving Common Embroidery Thread Problems

We've all been there. You're in the zone, your machine is humming along beautifully, and then... it happens. The thread snaps, you hear a clunk, or you find a tangled mess under your hoop. It’s frustrating, but take a deep breath! These little hiccups are part of the embroidery journey.

More often than not, these problems aren't a sign of a broken machine. They're just your machine’s way of telling you that something needs a small tweak. Think of yourself as a stitch detective—your thread is leaving clues, and learning to read them is the key to getting back to beautiful embroidery.

Why Your Thread Keeps Breaking

Constant thread breaks are easily the most annoying interruption to any project. Before you throw in the towel, run through this quick mental checklist. The solution is usually simpler than you think.

- Rethread Everything: Seriously. This is step one, always. Take the thread completely out of the machine and rethread the entire upper path. Make sure your presser foot is UP so the tension discs are open and can properly grab the thread.

- Check That Needle: A dull, bent, or even slightly damaged needle is a primary suspect. A good rule of thumb is to pop in a fresh needle after every 8-10 hours of embroidery. It makes a world of difference.

- Ease Up the Tension: If your upper tension is cranked too tight, the thread is more likely to snap under pressure, especially at high speeds. Try lowering it a notch or two and stitch a small test.

- Slow Down: While quality thread is designed for speed, sometimes you just need to ease off the gas. This is especially true for trickier threads like metallics or if you’re using an older spool that might be a bit brittle.

Taming the Dreaded Bird’s Nest

You finish an area, pull the hoop out, and find a giant, loopy clump of thread on the bottom. Ugh. The infamous "bird’s nest." It looks like a bobbin problem, but here’s the secret: it’s almost always caused by the top thread.

A bird's nest happens when the top thread isn't seated correctly in the tension mechanism. With no tension, the machine just dumps loose thread down below, where it gets tangled up with the bobbin thread. The fix is simple: completely rethread your machine from the spool down, making sure that presser foot is up.

Here's a pro-tip that will save you hours of frustration: If the mess is on the bottom of your fabric, the cause is almost always on the top of your machine. Burn that into your brain!

If you want more tips on keeping your machine happy, our guide on using Stitcher's Friend is packed with fantastic advice for routine care and maintenance.

When Thread Shreds or Frays

Ever see your thread looking a little fuzzy or even shredding as it stitches out? That’s a tell-tale sign of friction. Something is rubbing your thread the wrong way on its path from the spool to the needle.

First things first: change your needle. A tiny burr or a worn-out eye can act like sandpaper on your thread. If you're using delicate metallics or shiny rayons, swapping to a Topstitch or Metallica needle with a larger eye can be a game-changer. Also, glance at your spool—is the thread catching on the spool cap or getting snagged on the thread stand?

The technology in embroidery thread is always evolving to keep up with faster, more powerful machines. The industrial embroidery machine market was valued at around USD 2.10 billion in 2023, and that industry demands threads that can withstand incredible stress without a hint of fraying. You can see more about how these advancements are connected in these industrial embroidery machine market insights.

By working through these common issues step-by-step, you can solve most thread troubles that pop up. And for those really stubborn problems, don't hesitate to reach out—the team here at Linda's is always happy to share our experience and help you get your project back on track.

Your Embroidery Thread Questions Answered

No matter how much you learn, there are always little questions that pop up right in the middle of a project. It happens to all of us! To help you out, we’ve put together answers to some of the most common questions we hear about thread for embroidery machines.

Think of this as your personal cheat sheet for those moments when you need a quick fix. Getting these details right is what really takes your embroidery from a fun hobby to a true art form.

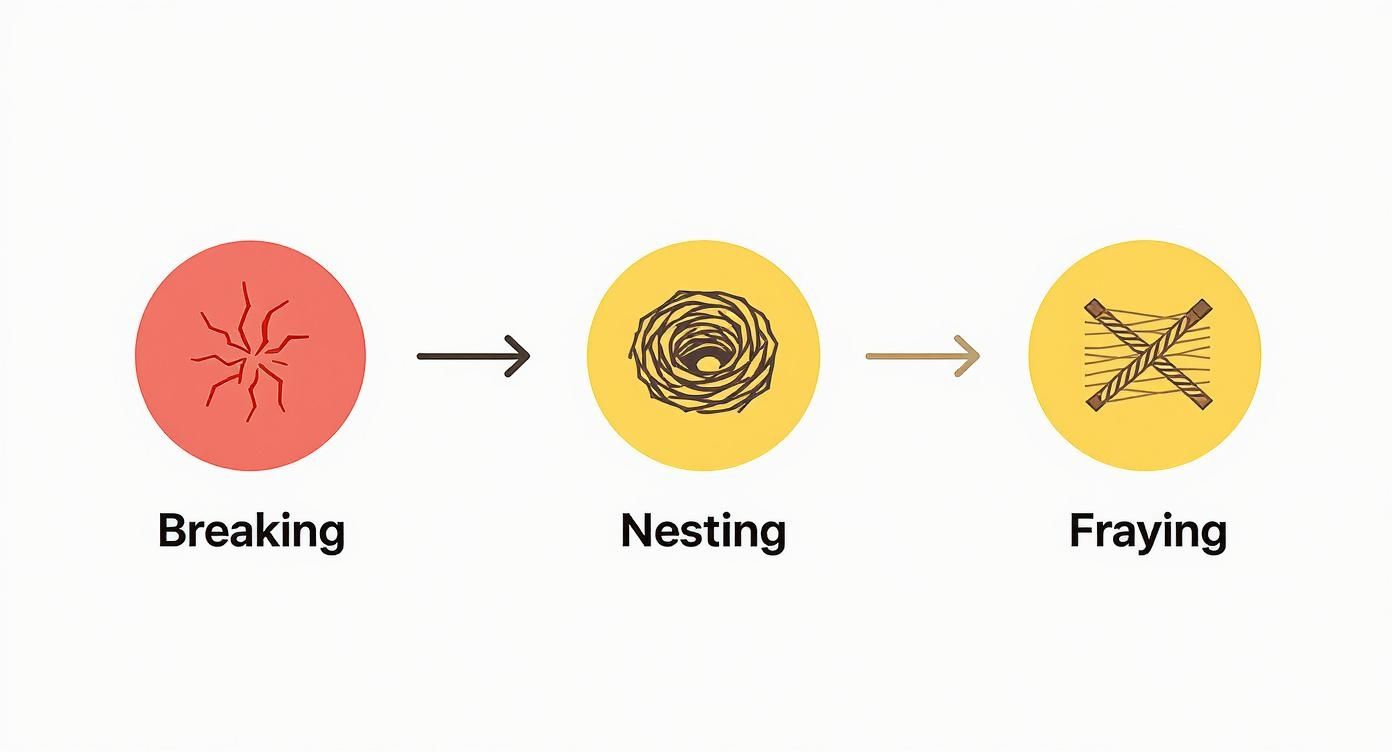

This little decision tree is a lifesaver for figuring out the big three embroidery headaches: breaking, nesting, and fraying. It’s designed to get you to the solution, fast.

As you can see, most issues come back to a handful of culprits, like using the wrong needle or having your tension off. Once you know what to look for, troubleshooting is so much easier than it seems.

Can I Use Sewing Thread in My Embroidery Machine?

It’s tempting, I know, but please don’t! Using regular sewing thread for machine embroidery is a shortcut you'll regret. Sewing thread is designed to be strong for construction, not shiny and decorative. It will make your embroidery designs look bulky, feel stiff, and lack that beautiful sheen we all love.

Worse yet, it simply wasn't made to handle the lightning-fast speeds of an embroidery machine. It will create a ton of lint, break constantly, and could even damage the delicate tension system on your machine over time.

Stick with thread made specifically for embroidery. It has the right strength and smooth finish to glide through your machine and create gorgeous, flexible designs. Your machine—and your projects—will thank you for it.

What Is the Best Way to Store Embroidery Thread?

You've invested in a beautiful collection of thread, so you'll want to store it properly to keep it perfect for every stitch. The two biggest culprits that will ruin your thread are sunlight and dust.

Sunlight's UV rays will weaken the thread fibers and fade those vibrant colors you paid for. Dust and lint are sneaky troublemakers that get into your machine's tension discs, causing all sorts of headaches.

The best way to store your thread is in closed, clear containers or on a thread rack with a cover. This keeps them clean, organized, and safe from light. Just make sure to store them in a cool, dry spot, and your thread will be ready to go whenever inspiration strikes.

Why Does My Metallic Thread Keep Breaking?

Ah, metallic thread. It creates the most spectacular results, but it can definitely test your patience. If your metallic thread keeps breaking, the problem is almost always friction.

First things first, you need a specialty needle. A Metallica or a Topstitch needle is a must-have. They have a larger, super-smooth eye that lets the delicate metallic thread pass through without getting shredded.

Next, slow your machine way down. High speeds generate heat and friction that metallic thread just can't handle. You might also need to loosen your top tension a tiny bit to help the thread flow better. With these little tweaks, you’ll be stitching with sparkle like a pro!

Quick Guide to Project-Specific Thread Selection

To pull everything together, we've created this handy reference chart. It matches common projects with our go-to recommendations for thread, needles, and stabilizers. It's the perfect starting point when you're kicking off a new creation.

| Project Type | Recommended Thread | Ideal Weight | Needle Size | Stabilizer Type |

|---|---|---|---|---|

| T-Shirts & Knits | Polyester | 40 wt | 75/11 Ballpoint | Cut-Away |

| Towels & Fleece | Polyester or Rayon | 40 wt | 80/12 | Wash-Away Topper & Cut-Away |

| Quilting Cotton | Cotton or Polyester | 40 wt | 75/11 | Tear-Away |

| Denim & Canvas | Polyester | 40 wt | 90/14 | Cut-Away or Heavy Tear-Away |

| Delicate Lettering | Polyester or Rayon | 60 wt | 70/10 | Tear-Away or Wash-Away |

| Freestanding Lace | Polyester | 40 wt | 75/11 | Heavy Wash-Away |

Remember, becoming a master of machine embroidery is all about learning as you go. The more you understand how all your materials work together, the more confident you'll feel tackling any project you can dream of.

Ready to put your new knowledge to the test? Linda's Electric Quilters has everything you need to bring your next embroidery masterpiece to life. From gorgeous threads to the right needles and stabilizers, we’re here to help you every step of the way.

Explore our extensive collection of embroidery supplies at Linda's Electric Quilters today!