Getting your sewing machine tension just right is the key to creating stitches that are both beautiful and strong. Think of it as a delicate balancing act between your top thread and the bobbin thread. When they lock together perfectly in the middle of your fabric, you get that professional look we all strive for. If you’re seeing frustrating loops or puckering, don't worry—a simple turn of the tension dial is often all it takes to fix it. This guide will walk you through the project of mastering your tension settings, ensuring every seam you sew is a success.

Demystifying Your Tension Dials

Imagine a friendly game of tug-of-war happening inside your sewing machine. The top thread and the bobbin thread are on opposite ends. When the pull from both sides is perfectly even, they meet and interlock right in the middle of your fabric layers. That’s the magic of a balanced stitch—it’s not just pretty, it's built to last.

The numbered dial on your machine, usually right on the front, controls the upper thread tension. This dial adjusts how tightly a pair of small metal discs grip your thread as it passes through. Crank the number higher, and the discs squeeze together, increasing the tension. Go lower, and they loosen up, letting the thread flow more freely.

The Anatomy of a Perfect Stitch

So what does a perfect stitch actually look like? Simple: it should look exactly the same on both the top and bottom of your fabric. The fabric itself should lie completely flat, with no signs of bunching or puckering. Most importantly, the spot where the top and bobbin threads meet should be tucked away, invisible inside the fabric layers.

Nailing this perfect stitch is why we fuss over tension settings. It's what gives our seams their strength and that clean, polished finish.

Here's a handy cheat sheet to help you quickly figure out what your stitches are telling you.

Quick Guide to Diagnosing Stitch Tension

Use this visual reference to quickly identify and solve common stitch problems by examining your top and bottom threads.

| What Your Stitch Looks Like | What It Means | How to Fix It |

|---|---|---|

| Top thread loops are visible on the bottom of the fabric. | Your upper tension is too loose. | Increase the upper tension (turn the dial to a higher number). |

| Bobbin thread is visible on the top of the fabric. | Your upper tension is too tight. | Decrease the upper tension (turn the dial to a lower number). |

| The stitch is identical on top and bottom; the fabric lies flat. | Your tension is balanced. | No adjustment needed. Keep sewing! |

Think of this table as your first stop for troubleshooting. A quick glance can save you a ton of guesswork.

Historical Roots of Tension Control

The struggle to balance thread tension isn't new; it's been at the heart of sewing machine design since day one. Early inventors quickly discovered that just a needle and thread weren't enough to create a strong lockstitch. This puzzle actually drove many of the biggest leaps in sewing technology.

The whole concept of adjustable tension evolved dramatically from the first machines in the mid-1800s. Elias Howe’s 1850s patent for a two-thread lockstitch machine highlighted the need for balanced tension. Just a few years later, Singer’s 1851 machine introduced a game-changing friction-pad thread controller, allowing for smoother stitches at speeds up to an incredible 900 stitches per minute. If you're a history buff, you can read more about these mechanical marvels on Treasurie's blog.

Key Takeaway: That tension dial isn't just a random knob. It's the product of over 150 years of engineering, all designed to give you precise control over your stitch quality. Knowing this empowers you to solve any tension problem that comes your way.

Common Signs of Imbalance

When that tension tug-of-war gets lopsided, your stitches will tell on you immediately. Here are the two classic problems you’ll run into:

- Loops on the Bottom: Seeing little loops of your top thread on the underside of your fabric? That’s a dead giveaway that your upper tension is too loose. The bobbin thread is winning the pull, yanking too much of the top thread down with it.

- Loops on the Top: On the flip side, if you see bits of the bobbin thread peeking through on the top of your fabric, your upper tension is too tight. The top thread is pulling way too hard, dragging that bobbin thread out of place.

Mastering these two fixes is your first step to becoming a tension pro. Of course, having the right supplies makes all the difference. For any project, from a simple quilt to a complex garment, Linda's has an amazing selection of high-quality threads and notions to help you get that perfect stitch every time. Explore our collection and find the perfect match for your next creation.

How to Test and Adjust Your Tension

Alright, let's move from theory to the sewing table. The absolute best way to get your tension settings just right is to stop guessing and start testing. This means making a little "test sandwich" with scraps of your actual project fabric and thread. Think of it as a dress rehearsal for your stitches—it's how you guarantee a perfect performance before the main event.

Before you even touch that tension dial, let's set the stage. A clean machine is a happy machine, period. When dust and lint build up in the bobbin case or along the thread path, they can create drag on your thread. This perfectly mimics a tension problem, but the real culprit is just a bit of fuzz that needs cleaning out.

Just as important? Start with a fresh needle. A dull, bent, or even slightly nicked needle can cause all kinds of headaches, from skipped stitches to puckered seams, which are so easy to mistake for tension issues. For any real accuracy, always start with a clean machine and a new needle that’s right for your fabric.

Creating Your Test Sandwich

First things first, grab a few scraps of the exact fabric you're using. If your project has multiple layers—like a quilt with batting or a lined jacket—your test scrap needs to be an exact replica. A single layer of fabric just won't give you an accurate read for a project with three layers.

Cut at least two pieces of fabric, stick any batting or interfacing between them just like in your project, and get ready to sew. It's also super important to use the same thread in both the needle and the bobbin for this test.

Pro Tip: Don't just sew a straight line and call it a day. Stitch some curves and a few zig-zags. Tension problems love to show up on curves and at sharp corners where the thread gets pulled in different directions.

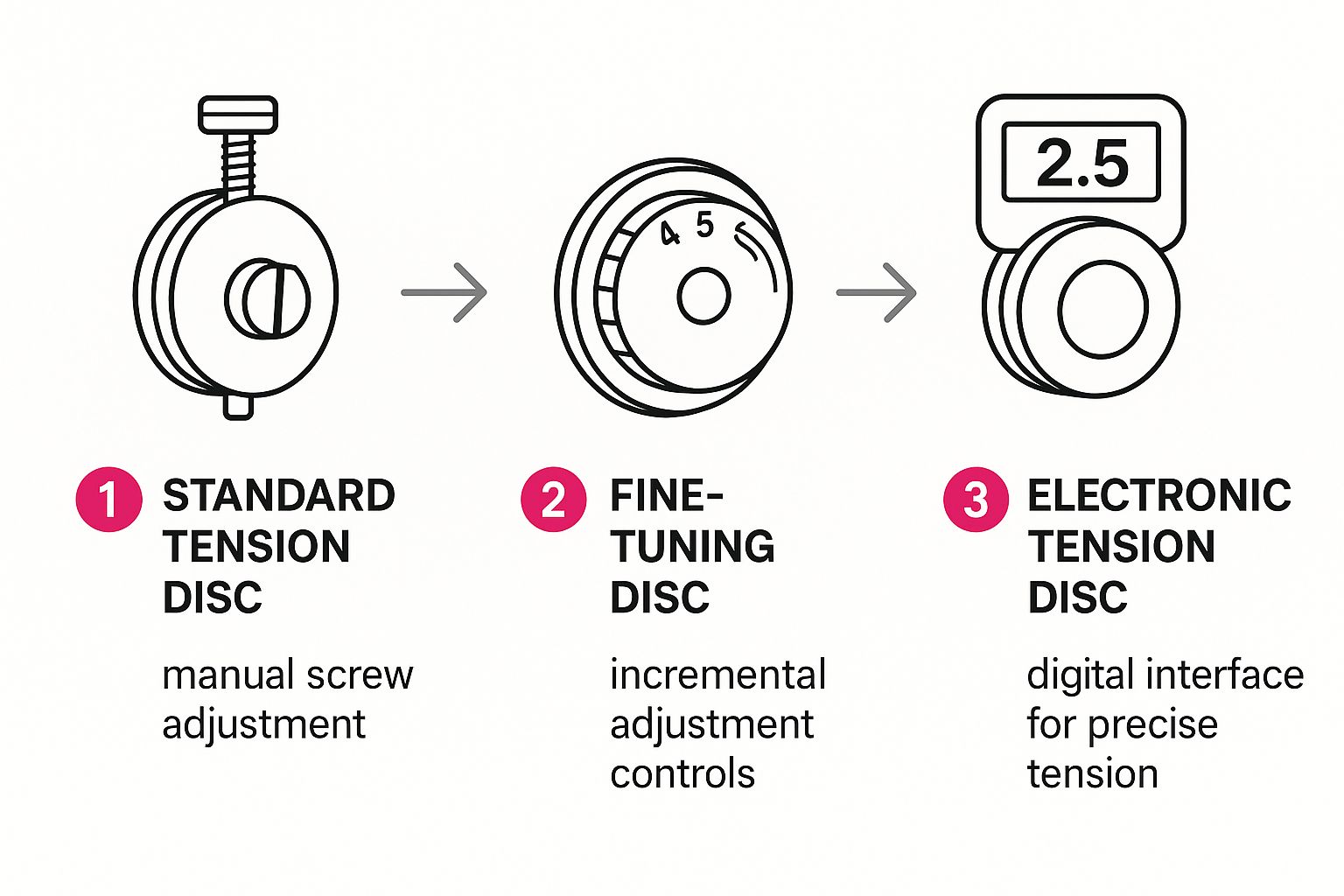

This image shows just how far tension disc technology has come, moving from simple manual knobs to incredibly precise digital controls.

This evolution from standard manual discs to fancy electronic systems really shows the push for making tension easier for all of us to manage.

The Systematic Adjustment Process

Now for the fun part. With your test sandwich under the presser foot, set your upper tension dial to the middle or "auto" setting. On most machines, this is somewhere around 4 or 5.

- Sew a Few Inches: Stitch a straight line for about three to four inches. No need to backstitch.

- Make a Small Adjustment: Turn the upper tension dial by just one full number. So, if you started at 4, move it to 5.

- Sew Another Line: Right next to your first line of stitching, sew another few inches.

- Repeat and Analyze: Keep doing this—making small, one-number changes to the dial and sewing a new line for each adjustment. You're creating a visual map of how each setting looks on your specific fabric.

This method takes all the guesswork out of the equation. You end up with a physical sample that shows you exactly how your fabric, thread, and needle are playing together at each tension number.

Analyzing the Results

Once you've got several lines of stitching, it's time to be a detective. Take the fabric out of the machine and look at it closely, preferably in good light.

- Look at the Top: Can you see tiny dots of the bobbin thread peeking through? If you do, your upper tension is too tight. The top thread is pulling way too hard.

- Look at the Bottom: Are there little loops of your top thread on the underside? This is a classic, and it means your upper tension is too loose. The bobbin thread is winning that tug-of-war.

- The Perfect Stitch: The sweet spot is a stitch line that looks exactly the same on the top and the bottom. The little knot where the two threads lock together should be buried perfectly between the fabric layers, completely out of sight.

Getting that beautiful stitch is all about mastering proper tension settings—a concept that's key in any fiber art, from sewing to crochet.

Once you find that perfect setting on your test scrap, jot down the number. Now you can move over to your real project feeling confident that your stitches will be strong, balanced, and gorgeous.

Matching Tension to Fabric and Thread

If there's one golden rule I’ve learned over the years, it's that your sewing machine tension settings are never a "set it and forget it" deal. Every single time you switch your fabric or thread, you’re creating a brand-new sewing environment that needs its own unique tension balance. It's like cooking—you wouldn't use the same heat for a delicate sauce as you would for a deep-fried turkey.

The weight of your fabric and the thickness of your thread are in a constant dance. They directly dictate how much force is needed to pull that top thread and bobbin thread together into a perfect, locked stitch right in the middle of the fabric.

The Logic Behind Lighter Fabrics

When you're working with something light and airy like silk, chiffon, or a delicate batiste, the fabric has almost no body to it. If your upper tension is cranked up too high, that top thread will yank the bobbin thread right through, causing the fabric to pucker and bunch up along your seam. It’s a frustrating sight we’ve all seen before.

To avoid this mess, you have to ease up. Dialing down your upper tension—often into the 2 to 3.5 range—reduces that pulling force. This lets the machine create a much softer stitch that allows your beautiful, delicate fabric to lie perfectly flat and smooth.

This becomes even more crucial if you're using a fine thread, like a 60wt or 80wt. That thread just doesn't have the muscle to fight against high tension, and the flimsy fabric offers zero resistance. The result is an ugly, strained-looking seam.

Tackling Heavy-Duty Materials

Now, let's flip the script. Think about tough materials like denim, canvas, or thick upholstery fabric. These guys need a strong, secure stitch that can punch through multiple layers without getting lost in the bulk. Using a low tension setting here would be a total disaster, leaving you with weak seams and visible loops on the bottom of your fabric.

For these heavyweight champs, you need to increase the tension. Cranking that dial up to a 5 or even a 6 gives the top thread the oomph it needs to form a tight lockstitch deep inside those fabric layers. This is especially true when you pair it with a heavier thread (like a 30wt or 40wt) designed for pure strength.

A higher tension setting gives the top thread the necessary strength to pull the bobbin thread up into the dense fabric, creating a powerful seam that won't fail under stress. It’s all about matching the force to the material's demands.

Specialty Threads and Their Unique Needs

Specialty threads are fun, but they definitely like to play by their own rules. They often require you to completely rethink your approach to tension.

- Metallic Threads: These are notoriously fussy. That delicate metallic foil wrapped around a core will shred if you look at it wrong. You absolutely have to lower your upper tension and, just as importantly, use a Metallic or Topstitching needle. The larger eye on these needles is a lifesaver, reducing the friction that causes all that shredding.

- Elastic Threads: When you’re shirring with elastic thread in the bobbin, you’ll almost always need to loosen your bobbin tension. To get that perfect gather, your upper tension will likely need to be a little higher than normal to properly tug on that stretchy bobbin thread.

- Monofilament (Invisible) Threads: This slippery nylon thread is another tricky one. It often needs a looser top tension. If it's too tight, the thread will stretch as it's stitched and then relax in the seam, causing puckers.

Getting these specialty projects right often comes down to having the right tools from the start. So much frustration is just a simple mismatch of thread, needle, and fabric. Grabbing a good specialty needle assortment and the right thread will save you from pulling your hair out.

Tension Starting Points for Common Fabrics

While you should always sew a test swatch, nobody wants to start from scratch. This chart will give you a solid starting point for your tension dial depending on what you're sewing. Set your machine here, run a quick test, and then fine-tune it to perfection.

| Fabric Type | Suggested Tension Range | Recommended Needle |

|---|---|---|

| Sheer/Delicate (Chiffon, Organza) | 2.0 - 3.5 | Microtex 60/8 or 70/10 |

| Lightweight (Cotton Lawn, Voile) | 3.0 - 4.0 | Universal 70/10 or 80/12 |

| Medium Weight (Quilting Cotton, Linen) | 4.0 - 5.0 | Universal 80/12 or 90/14 |

| Heavyweight (Denim, Canvas, Twill) | 5.0 - 6.0 | Jeans/Denim 90/14 or 100/16 |

| Knits/Stretchy Fabrics (Jersey, Spandex) | 3.5 - 4.5 | Ballpoint or Stretch 75/11 |

Think of this chart as your friendly guide, not a set of rigid rules. Things like thread quality, your specific machine's personality, and even the weather can subtly affect your stitch. The real goal is to get a feel for how all these pieces work together so you can confidently adjust your sewing machine tension settings for any project that lands on your cutting table.

Troubleshooting Common Tension Problems

So, you've done your tension test on a scrap, fiddled with the dial, and something is still not quite right. Before you start twisting that tension dial in frustration, just take a deep breath. More often than not, what looks like a tension meltdown is actually a symptom of a totally different—and much simpler—problem.

Jumping straight to the tension dial is a classic mistake that can send you down a frustrating rabbit hole of adjustments. Think of it this way: you wouldn't start rebuilding your car's engine just because it ran out of gas. We need to check the easy stuff first.

Your Pre-Tension Troubleshooting Checklist

Before you touch that dial again, run through this quick diagnostic checklist. It’s amazing how often the real culprit behind your stitch woes is hiding in one of these spots.

- Is the machine threaded correctly? This is, without a doubt, the number one cause of problems that look like bad tension. Unthread your machine completely—top thread and bobbin—and re-thread it from scratch. Critically, make sure the presser foot is up so the tension discs are open and can actually grab the thread properly.

- Is the needle fresh and the right type? A needle that's even slightly dull, bent, or nicked can wreak havoc, causing skipped stitches, puckering, and shredded thread. All of these perfectly mimic tension issues. Double-check that you're using the right size and type of needle for your fabric, and if it's been in there for a while, just change it.

- Is the bobbin area clean? Pop out your bobbin and its case. Grab a little brush and get rid of all the lint and dust bunnies that have moved in. That lint buildup can prevent the bobbin from spinning smoothly, which creates its own drag and messes with your bottom tension.

Seriously, working through these three simple checks will solve the vast majority of your sewing headaches. If your stitches still look off after all that, then it's time to dig a little deeper.

Identifying Subtle Stitch Issues

Sometimes the problem isn't obvious loops but something more sneaky. "Railroad tracks" are a perfect example. This is when your stitches look perfectly fine on the top, but when you flip your fabric over, you see two parallel lines of the top thread peeking through between each stitch. This is a dead giveaway that your needle tension is a little too tight, pulling that bobbin thread up too aggressively.

You might also see inconsistent stitch lengths or the occasional skipped stitch. This can happen if the thread is getting snagged somewhere along its path or isn't unwinding smoothly from the spool. Make sure you're using the correct spool cap for the size of your thread spool to guarantee a smooth, even feed.

Industry data shows that what we feel in our sewing rooms is true everywhere: approximately 60-70% of common sewing machine problems, from skipped stitches to wonky seams, trace directly back to incorrect upper or bobbin thread tension.

This just confirms that getting a feel for tension is one of the most valuable skills you can develop for high-quality results.

When to Consider Adjusting Bobbin Tension

Alright, let's talk about the one part of your machine you were probably told to never touch: the tiny screw on your bobbin case. And for 99% of your sewing projects, that is absolutely sound advice. Your bobbin case tension is set at the factory to be perfectly balanced for most standard sewing threads.

However, there are a few rare, specific times when a tiny adjustment is not only okay but necessary. This is almost always when you're using a non-standard thread in your bobbin.

- Shirring with Elastic Thread: This stuff is way thicker and stretchier than regular thread. You’ll have to loosen the bobbin tension to let it feed through without a fight.

- Using Heavy Decorative Threads: If you're doing bobbin work with a thick, metallic, or decorative thread, you will definitely need to loosen the tension quite a bit.

- Free-Motion Quilting with Fine Thread: Some quilters who use very fine silk or monofilament threads in the bobbin find that a minuscule adjustment helps them achieve that perfectly balanced stitch.

If you decide you have to adjust it, find a small screwdriver that fits the screw head perfectly. Turn it in tiny increments—we're talking a quarter-turn at most—and always remember "righty-tighty, lefty-loosey." A pro tip is to use a fine-tipped permanent marker to mark the original position of the screw slot so you can always find your way back to the factory setting.

In fact, many sewists buy a second bobbin case specifically for these specialty threads. That way, they can keep one at the default setting and use the other for experiments without any stress.

Ultimately, effective troubleshooting is just about being methodical. By checking the simple things first, you can find the real problem fast and get back to what you love—sewing. And of course, starting your project with the best materials, like high-quality threads and needles available at Linda's, can prevent many of these headaches from ever cropping up.

The Evolution of Tension Control

Have you ever really looked at the tension dial on your machine and appreciated the genius behind it? That ability to fine-tune your sewing machine tension settings with a simple twist is something we often take for granted. It's actually the result of more than a hundred years of tinkering and refinement, a journey from crude, frustrating mechanisms to the precise systems we have today.

Believe it or not, the earliest sewing machines had incredibly basic tension controls. We're talking about little more than a screw or a pin that the thread was wrapped around. Getting a balanced stitch was a constant battle of trial and error. As sewing machines made their way into more homes, manufacturers knew they had to make this process easier and more reliable.

From Manual to Automatic

The big breakthrough came when designers moved away from simple friction posts and developed the spring-loaded tension disc assemblies that are now standard. This design gives a much more consistent and measurable squeeze on the thread, which led to the numbered dials we all recognize. It was a huge leap, turning tension from a guessing game into a repeatable science.

This mechanical evolution continued for decades, with each new model offering subtle but important improvements. Iconic machines like the Singer Featherweight earned their legendary status not just for being portable, but for their incredibly dependable and precise stitch quality—a direct result of their brilliantly engineered tension systems.

When you understand this history, you start to see your sewing machine as more than just a tool. It’s a piece of living history. The core ideas of balancing thread have guided sewing innovation for generations, and that same logic applies whether you're working on a vintage treasure or a brand-new computerized model.

The Featherweight's Contribution

The beloved Singer Featherweight is a fantastic case study in this journey. Between 1935 and 1969, even a small part like the bobbin winder tension unit went through major changes, all aimed at boosting performance and making life easier for the user.

Early models had a top-mounted tension unit with an adjustable screw. This gave sewists precise control over how tightly the bobbin was wound, which is a critical piece of the stitch quality puzzle. You can actually see a visual timeline of how these Featherweight tension units advanced over time.

By the 1960s, the design had been simplified. Tension was now set by how the thread was routed through specific slots, which got rid of the need for user adjustment and cut down on potential mistakes. This kind of thoughtful simplification made high-quality sewing more accessible to everyone.

The Digital Age of Tension

The latest leap forward, of course, is the rise of computerized sewing machines. These modern wonders often have automatic tension systems that use sensors to read the fabric's thickness and adjust the tension on the fly.

While they seem like magic, they’re built on the very same principles that were perfected over the last 150 years. Knowing how we got from manual guesswork to automatic precision gives you a massive advantage. You understand the why behind the settings, which empowers you to troubleshoot any issue and get that perfect stitch from any machine, old or new.

To put that knowledge into practice, you'll want to start your next project with the right tools. A fresh pack of high-quality needles and threads from Linda's is always the best first step.

Answering Your Top Sewing Machine Tension Questions

Even when you feel like you've got the hang of it, tension troubles can sneak up on you mid-project. Let's tackle some of the most common questions that pop up, so you can solve them on the fly and get back to the fun part—sewing!

Why Are There Loops On The Bottom Of My Fabric?

This is the big one. If you see messy loops of thread on the underside of your fabric, it's a dead giveaway that your upper thread tension is too loose. Think of it as a tug-of-war between the top and bobbin threads; in this case, the bobbin thread is pulling way too much of the top thread down to the bottom with every stitch.

The fix is usually pretty simple: turn your upper tension dial to a slightly higher number. The key is to make small, one-number adjustments at a time. Sew a test line on a scrap of the same fabric after each change until those loops vanish and your stitch looks even on both sides.

Should I Ever Adjust My Bobbin Tension?

Honestly? Almost never. That tiny screw on your bobbin case came from the factory perfectly set for general sewing. It's the happy medium that works for the vast majority of threads and projects. Fiddling with it can easily cause more headaches than it solves.

Now, there are a few rare exceptions. You might need to make a tiny tweak (we're talking a quarter-turn at most!) for very specific techniques, like:

- Shirring with thick elastic thread in the bobbin.

- Creative bobbin work using heavy, decorative threads.

If you absolutely must adjust it, do yourself a favor and mark the original position of the screw with a fine-tipped permanent marker. That way, you can always find your way back to the default setting. A lot of experienced sewists even buy a second bobbin case just for these kinds of specialty projects.

Expert Insight: Think of it this way: the upper tension dial is your daily driver for adjustments. The bobbin screw is a specialty tool you pull out once in a blue moon. In my experience, well over 95% of tension problems are solved by adjusting the upper tension, completely re-threading the machine, or just swapping out the needle.

Can The Wrong Needle Affect My Tension?

You bet it can. This is a sneaky one because the symptoms—like skipped stitches or puckering—look a lot like classic tension issues. A needle that's old, dull, bent, or just the wrong type for your fabric can wreak havoc on your stitches.

A needle has one job: to slide cleanly through the fabric and make a perfect path for the thread. If it's damaged or the wrong size, it can snag the thread or create a hole that's too big, throwing off the whole stitch-forming process. This can easily trick you into thinking your tension settings are the problem when they aren't.

Why Does My Thread Keep Breaking?

Nothing stops a project in its tracks like thread that constantly snaps. Your first instinct might be to lower the tension, and while super-high tension can be the cause, it's not the only possibility. Before you start spinning the dial, run through a quick mental checklist.

Low-quality thread is often the real culprit; it can have weak spots that just can't handle the normal stress of sewing. Also, take a close look at your thread path. A tiny burr on the spool pin or a nick in the needle can shred thread as it passes by. Most often, though, the problem is a simple threading mistake. Always unthread the machine completely and re-thread from the beginning, making absolutely sure the thread snaps firmly into the tension discs.

Getting a feel for sewing machine tension settings is a huge step in making your projects look polished and professional. The other key ingredient? Starting with top-notch materials. At Linda's Electric Quilters, we've got a fantastic selection of high-quality threads, needles, and notions for whatever you're creating. Explore our collection today and get everything you need for your next masterpiece!