The sewing machine thread guide is the path the thread takes from the spool all the way down to the needle. It's a series of hooks, loops, and tension discs that might look intimidating at first, but they’re designed for one reason: to ensure your thread feeds smoothly and with the correct tension for any project.

Getting this right is the secret to creating strong, even stitches. Once you master the thread path, you're halfway to solving most common sewing frustrations and are well on your way to finishing your next project beautifully.

Your Guide to Flawless Sewing Machine Threading

Let’s be real—threading a sewing machine can feel like trying to solve a tricky puzzle, especially when you’re excited to start a new quilt or garment. But what if you started to see that thread guide not as a frustrating obstacle, but as your machine’s built-in map to perfect stitches? It’s this exact path that prevents tangles, stops thread from breaking, and gets rid of those ugly loops on the bottom of your fabric.

Learning this path is the first big step to really taking control of your stitch quality. It's a game-changer for sewing with confidence. Each little part has a job to do, all working in a specific order:

- The Spool Pin and Initial Guides: This is where it all starts. These hold your spool of thread and get it pointed in the right direction, heading toward the tension mechanism.

- Tension Discs: These are a big deal. They squeeze the thread with just the right amount of pressure, which is absolutely critical for creating balanced, professional-looking stitches for your projects.

- The Take-Up Lever: This is the part that bobs up and down. After every stitch, it pulls the thread back up, forming the loop that interlocks with the bobbin thread to create a solid lockstitch.

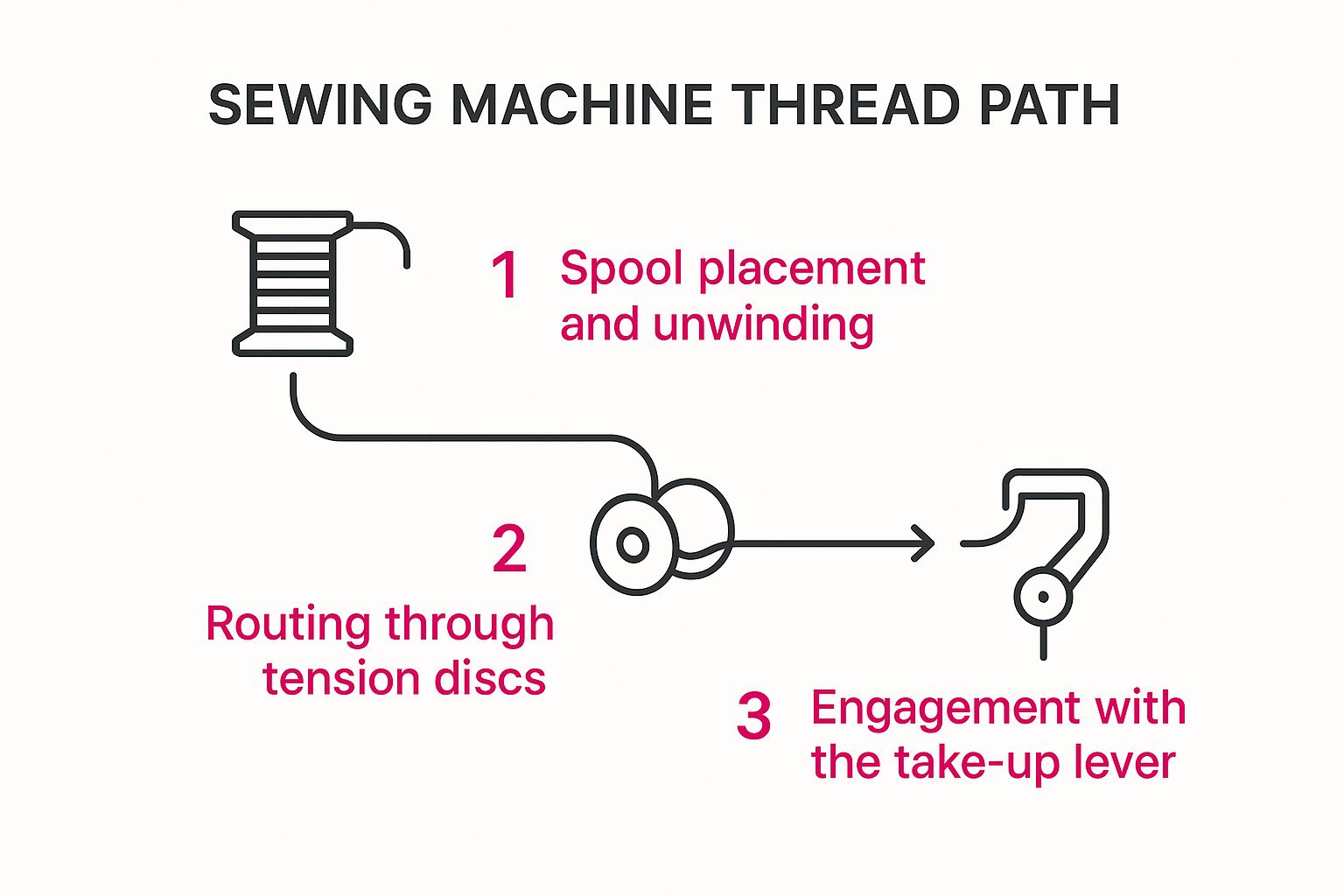

This infographic breaks down the basic journey your thread takes, from the spool, through the tension discs, and up through the take-up lever.

Think of each point on the guide as a checkpoint. Each one makes sure the thread arrives at the needle perfectly prepped to do its job. For those really tricky threads or if your eyes just need a little help, investing in a specialized craft light with a magnifying glass can make all the difference in your sewing space.

At the end of the day, a properly threaded machine is the foundation of every single successful sewing project you undertake.

Navigating the Thread Path From Spool to Needle

Threading a sewing machine might look like a complex puzzle at first, but I promise it’s a rhythm you’ll master quickly. Think of it as following a roadmap printed right on your machine. Whether you're working on a classic Singer, a trusty Brother, or a high-end Janome, the sewing machine thread guide follows the same basic logic. Most machines even have little numbers or diagrams printed right on them to help you out!

The goal is always the same: guide the thread from the spool pin all the way down to the needle, making sure it passes through the tension system correctly to achieve that flawless stitch.

Before you even touch the thread, do two things. First, always raise the presser foot. This one little step is crucial because it opens up the tension discs, letting the thread settle properly between them. If you forget and leave the foot down, the discs stay clamped shut, and your thread will just glide over the top—a surefire recipe for wonky stitches on your project. Second, turn the handwheel toward you until the take-up lever is at its very highest point.

The Key Checkpoints on Your Threading Journey

Your thread’s journey starts at the spool pin. From there, it passes through a couple of initial guides. These first few points are simple but important; they keep the thread flowing smoothly off the spool without it whipping all over the place.

Next, the thread path dips down into the tension assembly. Pay close attention here—this is where most threading mistakes happen. You have to make sure the thread gets seated firmly between the tension discs. If it just skims the outside, you’ll have zero tension on your upper thread, which leads to that dreaded mess of loops on the bottom of your fabric.

After the tension discs, the thread goes back up to the take-up lever—that’s the metal arm that bobs up and down while you sew. Hooking the thread through this lever is absolutely non-negotiable. It’s what pulls the thread from the spool to form the top half of each stitch. Missing this step is one of the biggest causes of those frustrating "bird's nests" of tangled thread that can ruin a project.

The modern sewing machine thread guide is a true marvel, but its basic principles have been around for ages. This very system was a game-changer during the Industrial Revolution. By 1864, thread companies were already making thread specifically designed for these new machines. You can learn more about this incredible history in the sewing revolution at Mill Museum.

Final Steps to the Needle

Once you’ve successfully conquered the take-up lever, you’re on the home stretch. The thread travels back down through a few more small guides on the face of the machine and right above the needle clamp. These last little checkpoints add stability, preventing the thread from twisting just before it gets to the needle.

Last but not least, thread the needle itself, usually from front to back (but always check your manual!). It might feel clumsy at first, but after a few times, it'll become pure muscle memory.

And of course, starting with the right materials makes every project easier. At Linda's, we offer a fantastic selection of high-quality threads made to glide right through your machine, helping you get that perfect stitch every single time. Stop by to find the perfect match for your next creation!

Choosing the Right Thread for Your Machine

The thread you choose can genuinely make or break your entire project. I’ve seen it happen! A thread that’s too thick, thin, or just plain poor quality will fight you every step of the way. You'll end up with snapped threads, frustrating shredding, and a surprising amount of lint building up inside your machine.

Matching your thread to your fabric is the golden rule of sewing. The goal is simple: use a thread with similar characteristics to the fabric you’re working with. This ensures the seams will wear, stretch, and wash at the same rate as the rest of the garment. For instance, a strong all-purpose polyester thread is a fantastic workhorse for most wovens and synthetic fabrics.

On the other hand, if you're quilting with natural fibers, a 100% cotton thread is usually your best bet. It has a soft, low-sheen finish that blends in beautifully and is less likely to slice through delicate cotton fabrics over time, making your quilt a true heirloom.

Understanding Thread Materials

Your project’s fabric and purpose will pretty much tell you which thread material to grab. While there are tons of specialty options out there for things like embroidery or upholstery, most of your sewing projects will rely on one of these common types.

To make it easier, here's a quick reference table to help you pick the right one at a glance.

Common Sewing Thread Types and Their Uses

| Thread Material | Best For | Strengths | Considerations |

|---|---|---|---|

| Polyester | General-purpose sewing, knits, synthetics, wovens | Strong, durable, slight stretch, resilient | Can be too strong for delicate natural fabrics |

| Cotton | Quilting, sewing with natural fibers (cotton, linen) | Soft finish, heat resistant (for pressing) | No stretch, can break under high tension |

| Silk | Fine fabrics (silk, rayon), tailoring, basting, detail | Fine, strong, smooth, minimal bulk | More expensive, can be slippery to work with |

This table covers the basics, but it's always smart to test a scrap of fabric first to see how the thread behaves.

Believe it or not, getting the thread right has always been the key to strong seams. A fascinating analysis of historic garments from Virginia Tech found that sewists between 1880 and 1909 consistently used a specific highly twisted thread to make sure their stitches lasted.

No matter what material you choose, stay away from poor-quality thread. If you hold it up and it looks fuzzy, has noticeable thick and thin spots, or snaps with just a gentle tug, it's going to cause you headaches.

Do yourself—and your sewing machine—a favor. To make sure your beautiful projects are built to last, stick with reliable, high-quality threads from Linda's. Your machine will thank you for it!

How to Fix Common Thread and Tension Problems

We’ve all been there. You’re cruising along a seam, and suddenly you see those frustrating loops on the back of your fabric or hear that dreaded snap of breaking thread. It’s so easy to blame the machine, but most of the time, these are classic signs of a simple threading or tension mix-up.

Luckily, the fixes are usually way easier than you think. Before you start twisting dials or calling for backup, remember this one golden rule: completely rethread your machine. I’m not kidding—90% of the time, this is the magic bullet. Just make sure the presser foot is up and the needle is at its highest point before you start.

Diagnosing Common Threading Issues

So, what are the tell-tale signs? The biggest one is a messy tangle of thread on the underside of your fabric, a phenomenon we lovingly call "bird's nesting." This is almost always a signal that something went wrong with your upper thread. It means there’s no tension holding it back, so it’s just feeding freely and getting tangled up with the bobbin thread.

Here are the usual suspects to check first:

- Missed Take-Up Lever: Your thread has probably slipped right out of the take-up lever. This is the number one cause of bird's nests, hands down.

- Skipped Tension Discs: The thread didn't settle properly between the tension discs. Always thread with the presser foot lifted! This opens the discs so the thread can sit snugly where it belongs.

- Incorrect Spool Cap: Using a spool cap that’s too big or too small for your thread spool can cause the thread to snag or feed unevenly, which throws the whole system out of whack.

The relationship between thread guides and the thread itself has been evolving for a long time. When machines gained new tricks like the zigzag stitch, which was patented by Helen Augusta Blanchard back in 1873, thread paths had to get more sophisticated. This pushed thread makers to create stronger, smoother threads to keep up, and that partnership continues to this day. You can learn more about the fascinating evolution of the sewing machine and how we got here.

Quick Troubleshooting for Threading Problems

Sometimes you just need a quick reference to figure out what's going on with your project. I've put together this little table to help you connect the symptom you're seeing to its most likely cause.

| Symptom | Common Cause | Quick Fix |

|---|---|---|

| Thread shredding or breaking | Thread path is snagging, old/bad needle, or poor-quality thread. | Rethread the machine carefully, change to a new needle, and try a different spool of thread. |

| Loops on fabric underside ("Bird's Nesting") | Upper thread has no tension (likely missed the take-up lever or tension discs). | Raise the presser foot and completely rethread the top of the machine. |

| Loops on fabric top side | Bobbin is threaded incorrectly, or the top tension is too tight. | Remove and re-insert the bobbin. If that fails, slightly lower the top tension dial. |

| Skipped stitches | Needle is dull, bent, or the wrong type for your fabric. | Install a brand-new needle that is appropriate for your project's fabric type. |

This isn't an exhaustive list, but it covers the vast majority of problems you'll run into. Start here before you assume it's a bigger mechanical issue.

Perfecting Your Stitch Tension

Okay, so you’ve rethreaded the machine perfectly, but your stitches still look a little… off. Now it's time to look at your tension. A truly perfect stitch looks exactly the same on the top and bottom of your fabric—the two threads should lock together right in the middle, hidden between the layers.

Pro Tip: Always, always test your tension on a scrap piece of the exact fabric and batting you're using for your project. A lightweight cotton will need a different setting than a heavy denim or a fluffy quilt sandwich.

To check your tension, just sew a straight line on your test scrap.

- See loops on the bottom? Your top tension is too loose. Turn the tension dial to a slightly higher number.

- See loops on top? Your top tension is too tight. Turn the dial to a slightly lower number.

Make small adjustments, one number at a time, and sew a new test line after each change. Keep going until your stitches are balanced and beautiful.

Fixing these issues really is just a process of elimination. Always start with the simplest solution—a good, careful rethreading—before moving on to tension adjustments. Once you get the hang of it, you’ll be troubleshooting like a pro. And when you're ready for your next project, you can find all the high-quality thread you'll need right here at Linda's Electric Quilters.

Keeping a Clean Thread Path for Better Stitches

Beautiful sewing isn't just about your skill—it's also about good machine habits. A clean sewing machine thread guide is one of those non-negotiable things for getting smooth, perfect stitches. Over time, that little path your thread follows can get absolutely packed with tiny fibers and dust.

Think of that buildup as a series of tiny speed bumps for your thread. It’s a classic culprit behind snags, shredding, and tension headaches that we often blame on bigger, more complicated problems. A quick, simple cleaning is usually all it takes to prevent a world of frustration and keep your projects looking professional.

Simple Cleaning Habits

Good maintenance doesn’t need to be a huge production. Just getting into the habit of doing a quick clean-up every few projects will keep your machine humming along and add years to its life.

- Little Brushes are Your Friend: Grab that small, stiff brush that probably came with your machine. Use it to gently flick away lint from all the visible guides, especially around the tension discs where it loves to hide.

- A Blast of Air: For those hard-to-reach spots, a can of compressed air is a lifesaver. It can dislodge stubborn dust from deep inside the tension assembly. Here's a pro-tip: always blow the dust out and away from the machine, not deeper into its gears.

A clean machine is a happy machine. I always say, lint is the mortal enemy of good tension. When you clear it out, you’re letting your thread glide through exactly the way it was meant to.

The quality of your thread makes a massive difference here, too. Bargain-bin threads are notorious for being fuzzy and leaving behind a ton of lint, which just gums up the works faster.

By choosing a higher-quality thread, you’re not just getting better-looking stitches; you’re also being kinder to your machine. To keep that thread path clear and your projects looking sharp, check out the incredible low-lint, high-performance options at Linda's Electric Quilters.

Answering Your Biggest Threading Questions

We get it. Threading issues can be maddening. We’ve all been there! So, let's walk through some of the most common questions we hear from fellow sewists to get you past those little roadblocks and back to creating beautiful projects.

"Why Does My Thread Keep Breaking?!"

You’ve threaded the machine perfectly, you’re sure of it, but the thread keeps snapping. It's a frustratingly common problem, and nine times out of ten, the culprit isn't your threading job at all.

Before you start questioning everything, check your needle. A dull, bent, or incorrect needle is the number one cause of shredding and breaking thread. If the needle is even slightly damaged or just the wrong type for your fabric, it’s going to fight the thread on every single stitch.

Also, take a look at your thread. That old spool you found in grandma's sewing basket might look fine, but thread gets brittle over time. Cheap thread just doesn't have the strength to keep up with a machine's pace. Always pop in a fresh, high-quality needle and use good thread before you start hunting for a bigger problem.

Does the Spool Type Really Matter?

Oh, absolutely! How the thread comes off the spool is the very first step in getting a good stitch, and different spools are designed to work in different ways. It’s a small detail that makes a huge difference to your final project.

- Stacked Spools: These are the ones where the thread is wound on in neat, straight layers. They work best on a vertical spool pin, where the thread can unwind smoothly off the side of the spool as it spins.

- Cross-Wound Spools: You'll see the thread is wound in a crisscross or "X" pattern on these. They need to go on a horizontal spool pin with a spool cap. This allows the thread to pull straight off the end of the spool without twisting or catching.

Using the wrong orientation can introduce weird twists and yanks before the thread even gets to the tension discs, causing all sorts of headaches.

Here's an easy way to remember it: If the thread is wound straight, the spool should sit straight up. If it's wound in a crisscross pattern, it should lie down. Getting this right is a game-changer for stitch quality.

When Should I Call a Pro to Service My Machine?

You can handle a lot of basic maintenance at home, like cleaning out lint and changing needles. But sometimes, your machine needs a little expert TLC. It’s time to call in a technician if you're experiencing any of these things:

- You hear persistent clunking, grinding, or other scary noises that don’t go away after a good cleaning.

- Your stitches are still a mess after you've tried every tension adjustment and troubleshooting tip you know.

- The machine is noticeably sluggish, seems to be struggling, or seizes up completely.

Think of it like a tune-up for your car. Getting your machine professionally serviced about once a year is a fantastic way to keep it humming along beautifully for years to come.

Ready to tackle your next project with total confidence? It all starts with the right materials. Linda's Electric Quilters has an amazing selection of high-quality threads, fabrics, and notions to make sure every stitch is a success. Explore our collection and get everything you need to finish your project delivered right to your door. Visit us at https://lindas.com to get started.